Grain Handling & Storage

For the grain industry, Mitchells provides solutions for:

- Grain reception, including dust extraction systems

- Cleaning

- Weighing

- Drying

- Storage

- Loading

- Conveying systems

- Automation

Expert, collaborative advice on everything from single pieces of equipment, to complete project solutions. Includes engineering, project management, supply, installation and commissioning.

Oilseed Conveying Solutions

Mitchells is a world leader in conveying equipment for oilseed crushing plants, with in-depth knowledge and experience of the entire crushing process: from storage and preparation, to solvent extraction and conditioning.

Mitchells can provide plant audits, plant revamps, maintenance programs and conveying system trouble shooting.

A focus on reliability, maintenance cost and energy saving maximises the return on your investment.

Standard equipment for oilseed includes:

- Belt conveyors

- En Masse chain conveyors

- Bulk Flow chain conveyors (up to 90 degree incline)

- Screw conveyors

Animal Feedmill Solutions

Mitchells designs and manufactures modular feedmills for the animal feed industry. Capacities from 5 – 20 mt/h.

The modular plants are delivered in containers and can be running within four weeks.

Plant features:

- Storage

- Grinding

- Mixing

- Conditioning

- Pelleting

- Cooling / drying

- Screening / pelleting

Mitchells also offer clean conveying and other bulk material handling solutions for the Animal, aqua & pet feed industry.

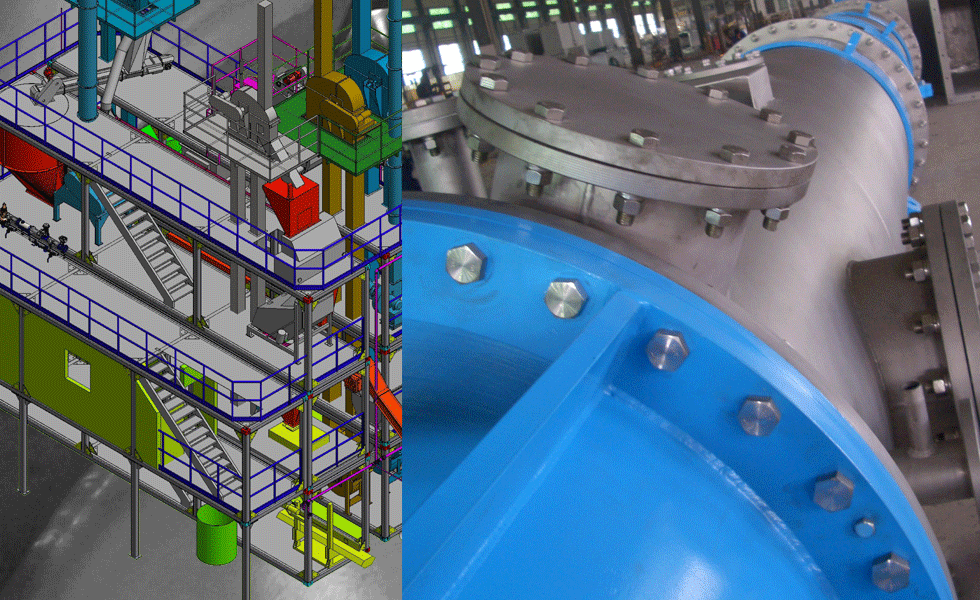

Customized Engineering & Manufacturing

Mitchells’ engineering department designs “customized equipment”, to suit specific functions or needs.

The Mitchells team use a collaborative approach, to ensure specific customer requirements are met when designing and manufacturing tailor made equipment.

Mitchells can assist throughout an entire project, from feasibility study until final commissioning.